Proportion of automotive injection molds on interior and exterior

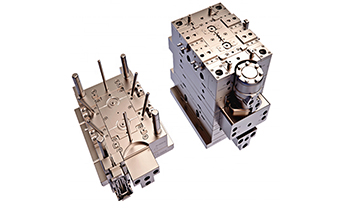

Behind the rapid development of the automotive industry is the development of the automotive mold industry. Especially in recent years, the development of the world automotive mold industry is changing with each passing day, and the demand for molds for automobiles is also growing. In a new car, about 500 pairs of automotive injection molds are needed. In the developed countries of the automotive industry, the market share of automotive products has exceeded 60%, and this trend continues to rise. It can be said that the injection mold has the largest proportion in the automobile mold, and the importance is self-evident.

Advanced technology for automotive interior and exterior molding molds

There is no essential difference between automotive injection molds and other injection molds, but they also have many of their own characteristics. Since the added value of automotive injection molds is generally high, many advanced technologies (such as sequential valve hot runner control technology, internal split profile technology, low pressure injection molding technology, etc.) are preferred to be developed and applied in automotive injection molds.

1. Sequence valve hot runner control technology (SVG technology)

The sequential valve hot runner control technology (SVG technology) is a new type of controlled hot runner technology. It is processed in sequence by the cylinder control to solve the problem of appearance defects of the traditional multi-point synchronous feed products. It can effectively avoid the defects such as weld lines and air pockets in the interior and exterior parts of the car, reduce the flow length, reduce the molding pressure, and play a huge role in the interior and exterior parts of the car with strict appearance requirements.

2. Low-pressure double-layer injection mold technology

The so-called low-pressure double-layer injection mold, also referred to as low-pressure injection mold, is a new type of injection mold technology. The traditional parts that are manually coated and vacuum-adsorbed by the male mold are directly injected into the mold. The main principle of the low-pressure injection mold is: the plastic injection pressure is lower on the cloth. When the mold is opened, the cloth should be hung on the front mold hanging needle, then the mold is clamped, injection molded, and finally taken. The products produced by this technology have a special soft fabric on the surface, which is greatly improved in decoration, hand feeling and aesthetics. Therefore, low-pressure injection mold technology is widely used in medium and high-end cars, generally used in automotive map bag skeletons, automotive ABC columns and other parts.

The main principle of the low-pressure injection mold is that the injection pressure is lower on the cloth. When the mold is opened, the cloth should be hung on the front mold hanging needle, mold clamping, injection molding, and then take the parts.

3. Automotive bumper internal parting injection mold technology

In automotive injection molds, for automotive bumper products, advanced internal parting technology is often used in mold design. The advantage is that the parting clip line is hidden on the non-appearing surface of the bumper, and the appearance of the clip line is not seen after assembly on the car, and the appearance of the product is not affected. However, this technology is more complicated and structurally difficult than the external type bumper, and the technical risk is also high. The mold cost and mold price are also higher than the external type bumper, but because of the beautiful appearance, in the middle and high-end cars. It is widely used.

Behind the rapid development of the automotive industry is the development of the automotive mold industry. Especially in recent years, the development of the world automotive mold industry is changing with each passing day, and the demand for molds for automobiles is also growing. In a new car, about 500 pairs of automotive injection molds are needed. In the developed countries of the automotive industry, the market share of automotive products has exceeded 60%, and this trend continues to rise. It can be said that the injection mold has the largest proportion in the automobile mold, and the importance is self-evident.

Advanced technology for automotive interior and exterior molding molds

There is no essential difference between automotive injection molds and other injection molds, but they also have many of their own characteristics. Since the added value of automotive injection molds is generally high, many advanced technologies (such as sequential valve hot runner control technology, internal split profile technology, low pressure injection molding technology, etc.) are preferred to be developed and applied in automotive injection molds.

1. Sequence valve hot runner control technology (SVG technology)

The sequential valve hot runner control technology (SVG technology) is a new type of controlled hot runner technology. It is processed in sequence by the cylinder control to solve the problem of appearance defects of the traditional multi-point synchronous feed products. It can effectively avoid the defects such as weld lines and air pockets in the interior and exterior parts of the car, reduce the flow length, reduce the molding pressure, and play a huge role in the interior and exterior parts of the car with strict appearance requirements.

2. Low-pressure double-layer injection mold technology

The so-called low-pressure double-layer injection mold, also referred to as low-pressure injection mold, is a new type of injection mold technology. The traditional parts that are manually coated and vacuum-adsorbed by the male mold are directly injected into the mold. The main principle of the low-pressure injection mold is: the plastic injection pressure is lower on the cloth. When the mold is opened, the cloth should be hung on the front mold hanging needle, then the mold is clamped, injection molded, and finally taken. The products produced by this technology have a special soft fabric on the surface, which is greatly improved in decoration, hand feeling and aesthetics. Therefore, low-pressure injection mold technology is widely used in medium and high-end cars, generally used in automotive map bag skeletons, automotive ABC columns and other parts.

The main principle of the low-pressure injection mold is that the injection pressure is lower on the cloth. When the mold is opened, the cloth should be hung on the front mold hanging needle, mold clamping, injection molding, and then take the parts.

3. Automotive bumper internal parting injection mold technology

In automotive injection molds, for automotive bumper products, advanced internal parting technology is often used in mold design. The advantage is that the parting clip line is hidden on the non-appearing surface of the bumper, and the appearance of the clip line is not seen after assembly on the car, and the appearance of the product is not affected. However, this technology is more complicated and structurally difficult than the external type bumper, and the technical risk is also high. The mold cost and mold price are also higher than the external type bumper, but because of the beautiful appearance, in the middle and high-end cars. It is widely used.